As an indispensable core equipment in the glass manufacturing industry, the importance of float glass furnaces is self-evident. The fused cast zirconia corundum (AZS) sidewall blocks, which serve as key components supporting the entire structure, play a critical role. These blocks are not only directly exposed to extremely harsh working conditions—including continuous high-temperature exposure, erosion by complex chemical components in the molten glass, and strong mechanical scouring from glass flow—but also bear the vital mission of maintaining the structural integrity of the furnace and ensuring the stability of glass quality.

Over time, the erosion of fused cast AZS sidewall blocks becomes increasingly prominent. The high-temperature environment causes physical and chemical changes in the block material, such as crystal phase transformation, volume expansion, or contraction, leading to decreased material strength and a loosened structure. Simultaneously, active components in the molten glass, such as alkaline oxides and fluorides, react chemically with the block material to form low-melting-point compounds. These compounds not only accelerate the erosion of the blocks but may also penetrate into the glass, affecting the uniformity of the glass composition and the performance of the final product. Additionally, the flow of molten glass, particularly during dynamic processes like bubble rise and liquid level fluctuations, scours the sidewall blocks, exacerbating surface wear and erosion. In severe cases, this may lead to structural damage of the furnace, compromising production safety.

Therefore, an in-depth understanding of the erosion mechanisms of sidewall blocks and the implementation of effective maintenance measures are of great significance for ensuring the long-term safe operation of the furnace.

3. Daily Maintenance of Sidewall Blocks

3.2 Melting End Sidewall Blocks

3.3 Waist Area Sidewall Blocks

3.4 Working End Sidewall Blocks

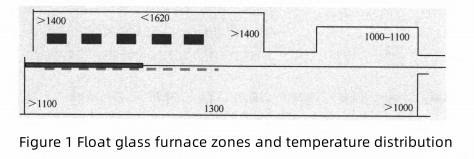

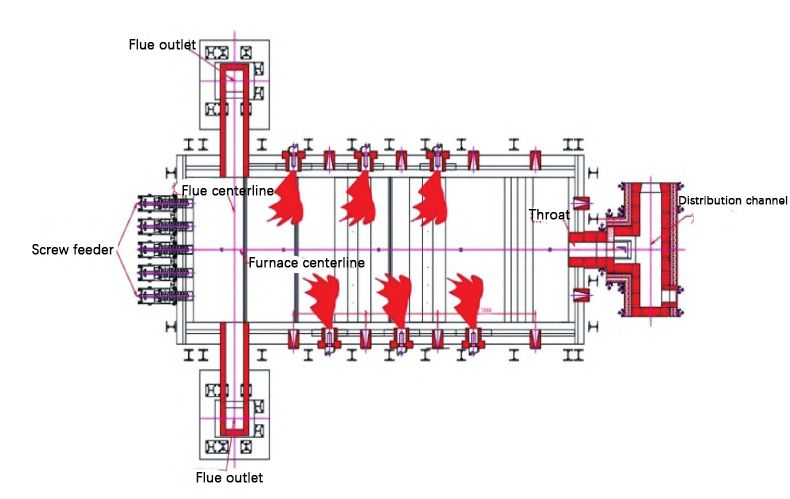

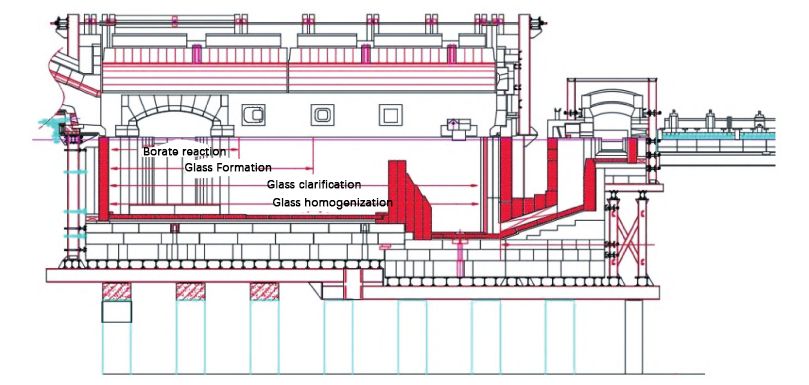

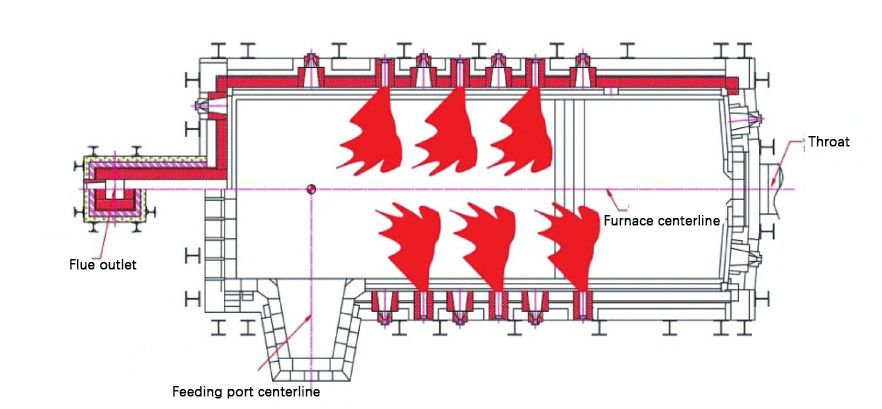

Float glass furnaces are essential melting installations in the glass manufacturing industry. They utilize advanced technologies such as oxygen combustion, where heat released from fuel combustion melts the batch materials to form molten glass. These systems are characterized by high efficiency, energy savings, and environmental friendliness, significantly enhancing production efficiency. Furthermore, the structural design and waste heat utilization technology of float glass furnaces further optimize energy use and reduce pollutant emissions, holding great importance for the sustainable development of the glass manufacturing industry. The float glass furnace is a cross-fired furnace, similar to conventional flat glass furnaces. Structurally, it can be divided into three parts: the melting end, the waist (or throat), and the working end. Typical zones and temperatures of a float glass furnace are shown in Figure 1.

As key components in float glass furnaces, fused cast AZS sidewall blocks suffer the most severe flow erosion due to their direct exposure to high temperatures and highly corrosive molten glass. This erosion not only accelerates the loss of the sidewall blocks but, more importantly, induces a series of quality issues in the molten glass. Specifically, erosion can lead to the formation of bubbles in the glass melt, which appear as defects in the finished glass, reducing product transparency and aesthetics. Simultaneously, erosion may promote the formation of stones—solid, unmelted particles encased in the glass—affecting its homogeneity and strength. Furthermore, continuous erosion can leave behind cord lines in the glass, causing surface unevenness in the product.

To improve the quality and production efficiency of glass products, newly built float glass furnaces must exercise extreme caution in material selection. The use of high-quality, highly erosion-resistant blocks is the preferred choice. These blocks should possess characteristics of stability at high temperatures and resistance to erosion by molten glass. However, when balancing material costs with actual production benefits, most furnace manufacturers choose to use cost-effective yet excellent fused cast AZS blocks in the most severely eroded areas, such as the melting end and waist. Due to their excellent erosion resistance and long service life, these blocks are the preferred material for constructing float glass furnaces.

2. Wear Mechanism of Fused Cast Sidewall Blocks

The wear mechanism of fused cast sidewall blocks is a complex process, influenced by both physical and chemical effects. In terms of physical effects, the furnace walls undergo repeated thermal shock from rapid heating and cooling during long-term operation, causing structural damage to the fused cast AZS blocks, increasing surface cracks, and loosening the structure.

Under the scouring action of gas flow, batch materials, and molten glass, the sidewall blocks are prone to cracking and spalling.

Chemically, fused cast AZS blocks are subjected to high-temperature molten glass over prolonged periods, leading to the gradual melting out of the glassy phase within the bricks. Concurrently, alkaline glass melt containing Na₂O infiltrates the blocks through pores and cracks in the fused cast AZS material and interacts with the exuded glassy phase, intensifying the erosion behavior. As the glass melt penetrates deeper, the skeletal minerals of the fused cast AZS blocks are gradually infiltrated and surrounded by the Na₂O-containing glass melt, eventually leading to the complete disintegration of the brick structure.

Chemically, fused cast AZS blocks are subjected to high-temperature molten glass over prolonged periods, leading to the gradual melting out of the glassy phase within the bricks. Concurrently, alkaline glass melt containing Na₂O infiltrates the blocks through pores and cracks in the fused cast AZS material and interacts with the exuded glassy phase, intensifying the erosion behavior. As the glass melt penetrates deeper, the skeletal minerals of the fused cast AZS blocks are gradually infiltrated and surrounded by the Na₂O-containing glass melt, eventually leading to the complete disintegration of the brick structure.

Ordinary float glass is generally soda-lime-silica glass, with a density of approximately 2.59 g/cm³. Wear of the fused cast sidewall blocks occurs on the surface in contact with the glass melt, with the most severely eroded area typically being the glass level line. Under the combined action of high temperature and liquid flow, the glassy phase and corundum phase in the sidewall blocks gradually spall off, leaving behind only the ZrO₂ crystalline phase. As these remain below the glass level for years, the ZrO₂ gradually transforms into spherical baddeleyite.

When the glass level fluctuates significantly, these spherical baddeleyite particles can spall off and fall into the glass, affecting its quality. Observing the erosion of fused cast AZS blocks vertically, for soda-lime-silica glass, due to the higher density of the dissolved products, the sidewall erosion is more severe at the top and lighter at the bottom.

In contrast, for lead glass, due to its different density, the sidewall erosion pattern is opposite to that of soda-lime-silica glass, with the most severe erosion occurring in the lower part of the sidewall. For the entire furnace, the sidewall blocks in the hot spot area of the combustion zone experience the most severe erosion due to the high temperature and lower viscosity of the glass melt.

Furthermore, pulsed bubblers are often used in the production of colored glass, which further accelerates the erosion rate in this area. Since the temperature in the working end is below 1200°C and more erosion-resistant materials are selected, erosion there is very slight.

3. Daily Maintenance of Sidewall Blocks

There are two primary methods to reduce wear on sidewall blocks: air cooling and water cooling.

Air cooling is the most common form of cooling, particularly when the sidewall blocks have worn too thin. Air cooling significantly reduces the internal surface temperature of the sidewall blocks, greatly slowing the erosion rate.

Another common method involves the installation of interstitial water packets. While effective in reducing the sidewall wear rate, their use has become increasingly less common due to the significant associated increase in furnace energy consumption and the considerable risk of water leakage.

Due to the lower temperature, the glass flow against the sidewalls in the doghouse area is not intense, and they are usually not scoured to failure within one campaign. For sidewall blocks in the doghouse area, wear primarily occurs in the middle section, related to the center clearance of the feeder. A larger gap results in stronger backflow and more severe erosion.

Feeder center clearances vary from 140 mm to 500 mm. For feeders with a small gap, sidewall erosion is minimal. If a large-gap feeder is used, after more than 12 years of furnace age, the wear condition of the sidewalls must be closely monitored. If necessary, measures such as applying water jackets or block tying should be taken to extend the furnace life.

Since the sidewall blocks are located above the feeder, daily maintenance should pay special attention to keeping them clean. Once a large amount of batch material accumulates, it poses a significant risk when the feeder is pulled out.

3.2 Melting End Sidewall Blocks

In the combustion zone, erosion of sidewall blocks is most severe in the hot spot area. In the absence of interstitial water jackets, typically in the fourth or fifth year of the furnace campaign, the first tying of blocks is performed on the sidewall blocks around the hot spot area, depending on the extent of erosion. For example, a furnace designed for a 10-year campaign with 6 pairs of ports usually undergoes its first block tying in the fifth year, typically in the area around ports #3 to #5.

For the remaining ports in the combustion zone, depending on the actual wear condition, tying in the remaining areas of the combustion zone can be considered around the 7th to 8th year. If aiming to extend the furnace campaign beyond 10 years, a second tying of weakened areas of the sidewall should be considered around the 9th year.

3.3 Waist Area Sidewall Blocks

The entrance corners of the waist area represent particularly vulnerable points in the sidewall block configuration, where structural erosion intensifies significantly due to the combined effects of reduced cross-sectional area and consequent increase in glass flow velocity. This area‘s complex geometry creates turbulent flow patterns that accelerate wear at these critical junctions. The presence of numerous interconnected steel structures and support systems in this zone further complicates accessibility, making routine visual inspections and physical maintenance procedures exceptionally challenging.

During the initial furnace commissioning phase, the strategic installation of specially designed corner water jackets in direct contact with the sidewall surfaces has proven to be an effective protective measure. These cooling systems function by establishing a stabilized thermal barrier that significantly reduces the rate of chemical corrosion and mechanical erosion.

When implementing waist water jackets for cooling protection, it is absolutely critical to ensure perfect contact between the cooling units and the refractory surfaces along both interfaces. Any residual gaps, however minimal, will inevitably create channels for preferential glass penetration and accelerated erosion, a condition that progressively worsens throughout the furnace campaign and may ultimately compromise the entire block assembly‘s structural integrity.

Regular monitoring of these critical interfaces using thermal imaging cameras is strongly recommended to detect early signs of cooling system inefficiency or gap formation.

3.4 Working End Sidewall Blocks

The working end sidewall blocks are constructed using premium-grade fused cast AZS (Alumina-Zirconia-Silica) materials specifically engineered for enhanced erosion resistance. This material selection, combined with the relatively milder operating conditions in this zone - including lower temperatures (typically below 1200°C) and reduced glass turbulence - results in minimal erosion throughout the furnace campaign.

The stable thermal environment and decreased chemical aggressiveness of the glass in this section further contribute to the blocks‘ exceptional durability. Regular inspections typically reveal only superficial wear at the glass contact surface, with annual erosion rates generally remaining below 0.5 mm.

At the conclusion of a standard 8-10 year furnace campaign, comprehensive evaluation consistently demonstrates that these sidewall blocks maintain sufficient thickness and structural integrity for continued service.

Replacement is typically unnecessary unless inspections reveal specific issues such as localized severe wear, structural cracks, or joint degradation that could compromise furnace integrity or glass quality.

As the most critical component of the float glass furnace structure, the durability and stability of the sidewall blocks are directly related to the operational life of the entire furnace, i.e., the length of the campaign. Sidewall blocks are exposed to extremely high temperatures and highly corrosive molten glass environments for extended periods, enduring significant pressure and challenges. Therefore, selecting materials with better performance and stronger erosion resistance for manufacturing sidewall blocks is an important prerequisite for enhancing the overall performance of the furnace and extending its service life.

Simultaneously, relying solely on high-quality materials is insufficient; scientific maintenance is also crucial. Regular inspection, cleaning, and necessary repair work can timely detect and address potential hazards, preventing minor issues from escalating into major failures. Through a proper maintenance plan, we can ensure that the sidewall blocks remain in optimal working condition, thereby guaranteeing the safe and efficient operation of the entire glass production line.

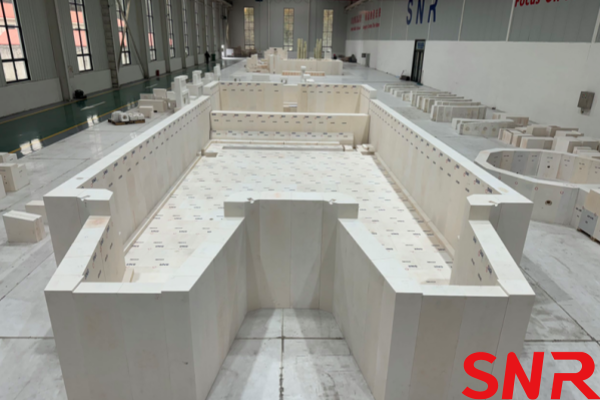

Henan SNR Refractory Co., Ltd. has been specializing in the production of fused cast AZS blocks for about 25 years. We use high-quality raw materials and advanced fusion technology to provide customers with high-quality products. From raw material procurement to finished product delivery, every step is strictly quality inspected to ensure that every indicator meets the standards, so you can use it with confidence.

If you have any needs, you can contact me at any time.

If you have any needs, you can contact me at any time.

Web: www.snr-azs.com

Email:wendy@snrefractory.com