In the modern glass production industry, the glass furnace, as the core thermal equipment, plays a decisive role in the quality, efficiency, and cost of glass production, holding a pivotal position. Glass production involves a series of complex physical and chemical processes, including the melting of the batch, refining and homogenization of the glass melt, and subsequent forming processes. The glass furnace is the key site where these processes occur, providing the necessary high-temperature environment and physical space, and is thus regarded as the heart of glass production.

The glass furnace sidewall, as a critical component of the glass furnace structure, is in direct contact with the high-temperature glass melt, batch materials, and high-temperature flames, playing an indispensable role in the glass production process. The main functions of the sidewall include: defining the spatial boundaries of the glass melt, ensuring that processes such as melting, refining, and homogenization occur within a specific area, and maintaining the structural integrity of the glass furnace interior; withstanding the static pressure and mechanical scouring of the glass melt, as well as chemical erosion and thermal shock from the batch and flames, thereby protecting other glass furnace structures from damage caused by high temperatures and chemical substances; and to some extent, influencing heat transfer and temperature distribution within the glass furnace, indirectly affecting the melting and homogenization processes of the glass melt.

1. Key Factors Influencing the Selection of Refractory Blocks for Glass Furnace Sidewalls

(I) High-Temperature Performance Requirements

The sidewalls of a glass furnace are constantly exposed to high temperatures during production, typically ranging from 1400 to 1600°C, and even higher for certain special glass types. At such high temperatures, refractory blocks must possess high refractoriness to ensure they do not soften or melt within the glass furnace‘s operating temperature range, maintaining their basic physical form and structural integrity. Refractoriness is a crucial indicator for evaluating the high-temperature performance of refractory blocks; generally, refractoriness for blocks used in glass furnace sidewalls should be no less than 1750°C.

Besides refractoriness, good high-temperature stability is essential. This refers to the block‘s ability to resist physical and chemical changes at high temperatures. Prolonged exposure can alter the crystal structure and mineral composition of the block, leading to performance degradation. For example, some mineral phases might undergo recrystallization or phase transformation, causing volume changes and internal stress, resulting in cracking or spalling. Therefore, sidewall blocks should have a stable high-temperature crystal structure and chemical composition to ensure performance stability throughout the glass furnace campaign.

Additionally, creep resistance is an important aspect. Creep is the slow plastic deformation of a material under constant temperature and stress over time. In the sidewall, blocks bear their own weight, the static pressure of the glass melt, and pressure from high-temperature gases. Under combined stress and high temperature, insufficient creep resistance can lead to gradual deformation, causing uneven sidewall thickness and affecting glass furnace operation and lifespan. Thus, sidewall blocks should possess good creep resistance to maintain shape stability under high temperature and stress.

(II) Resistance to Chemical Erosion

The glass melt is a complex multi-component system, and its chemical characteristics significantly influence the erosion behavior on the sidewall refractory blocks. The main components include SiO₂, Na₂O, CaO, MgO, along with trace impurity elements and additives. These components are highly chemically active at high temperatures and can react with the block‘s constituents, causing erosion and damage.

Alkaline oxides (e.g., Na₂O) have a notable erosive effect. They react with silica in the blocks to form low-melting-point silicate compounds. For instance, Na₂O reacting with SiO₂ forms sodium silicate (Na₂SiO₃), which has a relatively low melting point and may be liquid or softened at glass furnace operating temperatures, weakening the block‘s structural strength and accelerating erosion. Other components like CaO and MgO can also react with the blocks, forming new compounds and altering their composition and properties.

Furthermore, certain additives and impurities in the batch can also cause chemical erosion. Additives like fluorides or borides, used to lower melting temperature or modify glass properties, may volatilize or undergo complex reactions with the melt and blocks at high temperatures. Impurities such as iron or aluminum oxides can also participate in reactions, exacerbating block damage.

Therefore, to resist chemical erosion from the glass melt and batch, sidewall blocks need good chemical erosion resistance. This requires that the block‘s chemical composition be compatible with the glass melt, minimizing reactive tendencies, or capable of forming a dense protective layer to prevent further erosion. Using high-purity raw materials to reduce reactive impurities, or selecting chemically stable materials like zirconia-based refractories, which offer good resistance to glass melt erosion, are key strategies.

(III) Withstanding Mechanical Scouring

During glass furnace operation, the glass melt is in constant motion, its flow velocity and direction influenced by glass furnace design, temperature distribution, stirring, etc. This flow causes mechanical scouring on the sidewalls, particularly in specific areas like inlets/outlets, corners, and near stirrers, where scouring is more intense.

Mechanical scouring gradually wears away the surface material of the refractory blocks, leading to thinning. As wear progresses, the block‘s strength decreases, potentially leading to failure under static pressure or other forces, causing sidewall breach and impacting glass furnace operation and lifespan. Additionally, scouring can destroy protective layers or eroded surfaces on the block, making chemical erosion more likely and accelerating damage.

To withstand mechanical scouring, sidewall blocks must possess sufficient strength and abrasion resistance. Strength refers to the ability to resist external force destruction, including compressive and flexural strength. Higher strength ensures the blocks do not fracture easily under impact and friction. Abrasion resistance relates to the ability to resist wear, often associated with hardness and microstructure. blocks with higher hardness and denser microstructure generally have better abrasion resistance.

In practice, selecting appropriate refractory materials and optimizing manufacturing processes can enhance strength and abrasion resistance. For example, using corundum-based refractories, which have high hardness and strength, can effectively resist scouring. Process controls like raw material particle size distribution, forming pressure, and firing temperature can create a denser microstructure, improving strength and wear resistance. Additional measures like installing wear-resistant linings or increasing block thickness in high-scour areas can also extend sidewall life.

(IV) Thermal Shock Resistance

During glass furnace operation, start-ups, shutdowns, heating, cooling, and production temperature fluctuations subject the sidewall blocks to thermal shock. Thermal shock occurs when a material experiences rapid temperature changes, generating significant internal thermal stress. If this stress exceeds the material‘s limit, it causes cracking, spalling, or other damage.

During start-up, blocks heat rapidly from ambient to high temperature. Differential expansion between the surface (heating faster) and interior creates tensile stress on the surface, potentially causing cracking if it exceeds the tensile strength. During shutdown, rapid cooling causes surface contraction, generating compressive stress that can also damage the block.

Furthermore, temperature fluctuations during production due to fuel supply variations or operational instability can cause repeated thermal shocks. Long-term thermal shock leads to gradual propagation and interconnection of internal cracks, ultimately causing spalling and failure.

Therefore, sidewall blocks need good thermal shock resistance (thermal spalling resistance) to withstand rapid temperature changes without cracking or spalling. This property is closely related to the block‘s thermal expansion coefficient, thermal conductivity, and modulus of elasticity. Generally, blocks with low thermal expansion, high thermal conductivity, and low modulus of elasticity exhibit better thermal shock resistance. For example, silicon carbide refractories have low thermal expansion and high thermal conductivity, allowing rapid heat distribution, reducing internal temperature gradients and thermal stress, thus offering good thermal shock resistance. Structural improvements like composite designs or buffer layers can also enhance this property.

2. Common Types of Refractory Blocks Suitable for Glass Furnace Sidewalls and Their Properties

- Fused Cast AZS Blocks (Alumina-Zirconia-Silica)

- Fused Cast Alumina Blocks

- Fused Silica Blocks

- Silica Blocks

- Fireclay Blocks

- High-Alumina Blocks

(I) Fused Cast AZS Blocks (Alumina-Zirconia-Silica)

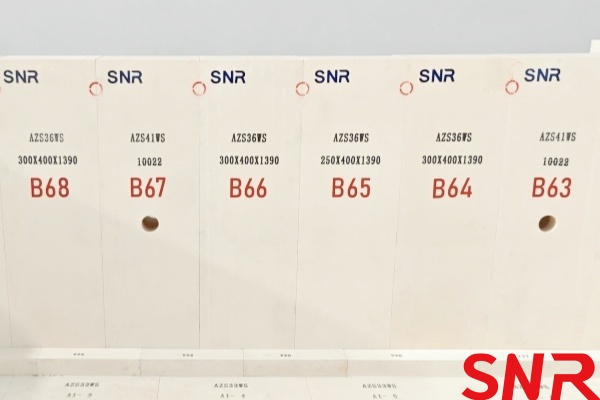

1. Composition and Classification: Fused cast AZS blocks, abbreviated as AZS, primarily consist of alumina (Al₂O₃), zirconia (ZrO₂), and silica (SiO₂). They are classified based on ZrO₂ content, common grades being AZS33%, AZS36%, and AZS41%. For example, AZS33# indicates approximately 33% ZrO₂ content. They are typically produced by melting a precisely proportioned mixture of selected zircon sand and industrial alumina powder, with small additions of fluxes like soda ash (providing Na₂O) or borax (providing B₂O₃), in an electric arc furnace at 1800-1900°C, followed by casting. Using partially desilicated zircon sand can produce blocks with 36%-41% ZrO₂.

2. Performance Advantages: Fused cast AZS blocks exhibit exceptional resistance to glass melt erosion, primarily due to their unique mineralogical structure comprising corundum-zirconia eutectoid and a glassy phase. The primary crystal phases, corundum (α-Al₂O₃) and baddeleyite (ZrO₂), possess excellent inherent erosion resistance. The glassy phase fills the inter-crystalline spaces. When eroded by the high-temperature glass melt, this phase forms a high-viscosity albite-based glass layer, further increased in viscosity by dissolved ZrO₂. This viscous layer adheres to the block surface as a protective film, hindering further erosion. Erosion resistance improves with increasing ZrO₂ content. ZrO₂ has a high melting point (~2700°C) and good chemical stability, offering strong corrosion resistance to both acidic and alkaline media, especially glass melts.

They also possess good thermal shock resistance, with a significantly lower thermal expansion coefficient than ordinary refractories, enabling them to withstand thermal cycling and reduce cracking risk from thermal stress. They demonstrate excellent high-temperature stability, high refractoriness, maintaining structure for 500 hours at 1800°C without spalling, and retaining over 85% hot strength at 800°C, far exceeding ordinary refractories, ensuring long-term stable performance in furnace environments. Additionally, they have high mechanical strength (compressive, flexural) and can withstand heavy loads and mechanical impact at high temperatures, with notable abrasion resistance.

3. Application Scenarios: Different ZrO₂ content AZS blocks are used in different parts of the glass furnace sidewalls. Grades with 33% and 36% ZrO₂ are commonly used for constructing melting end sidewalls, breast walls in the combustion space, burner ports, burner arches, burner blocks, and throat arches. AZS33#, with its dense microstructure, offers good erosion resistance and minimizes stone defects, making it the most widely used product in glass furnaces, suitable for the superstructure of the melting end, sidewalls and paving of the working end, and forehearths. AZS36#, with increased interlocking ZrO₂ crystals and lower glass phase content, offers enhanced erosion resistance, suitable for areas with higher glass flow velocity or temperature, such as sidewalls near the hot spot in the melting end.

AZS41#, with 41% ZrO₂, contains more uniformly distributed ZrO₂ crystals alongside the alumina-silica eutectic. Within the AZS system, it offers the highest erosion resistance and is selected for critical areas like sidewall corners and throat areas where glass melt scouring and erosion are most severe, balancing the lifespan of these areas with others to ensure overall glass furnace stability.

(II) Fused Cast Alumina Blocks

1. Composition and Characteristics: Fused cast alumina blocks, also known as α-β alumina blocks, are primarily made from high-purity alumina with small additions of soda ash, melted at ultra-high temperatures of 2000-2200°C. Their crystal structure consists of 45%-55% α-Al₂O₃ and 45%-60% β-Al₂O₃. The significant amount of β-Al₂O₃ interwoven with α-Al₂O₃ crystals transforms the typically tubular microstructure of α-Al₂O₃ into a platelet-like structure with much finer crystals. This unique structure imparts distinct performance advantages.

2. Performance: Fused cast alumina blocks exhibit extremely high resistance to glass penetration and almost no contamination of the glass melt, making them valuable in high-purity glass production. Their high-temperature performance is also excellent: high refractoriness, stable physical and chemical properties at glass furnace temperatures, good high-temperature structural strength to withstand mechanical loads and thermal stress without softening, deformation, or melting. Their crystal structure also confers relatively good thermal shock resistance, allowing them to withstand certain degrees of rapid temperature change without cracking or spalling.

3. Sidewall Applications: Due to their superior properties, fused cast alumina blocks are widely used in several key parts of glass furnaces. In the working end sidewalls, their anti-penetration and non-contaminating properties ensure glass quality during melting and refining. In the glass furnace bottom, they withstand the static pressure and chemical corrosion of the high-temperature glass melt, ensuring structural stability. In forehearths, their good abrasion and erosion resistance adapt to high flow velocities, reducing wear and ensuring smooth glass flow. They are also crucial in working end forehearth sidewalls and bottoms, where contact with the glass melt and strict limits on contamination exist, providing reliable support for high-quality glass production.

1. Basic Characteristics: Fused silica blocks primarily consist of high-purity silicon dioxide (SiO₂), typically over 99%. Using special production techniques, high-purity silica is crushed, screened, mixed with small amounts of auxiliary materials like clay and feldspar, and then formed under high pressure and fired under non-isothermal conditions to form a dense quartz crystal structure. Density is usually 1.9-2.0 g/cm³, refractoriness around 1650°C, and service temperature around 1600°C. Their appearance is gray-white due to sealed bubbles, resembling smooth porcelain with a slight opacity. Bubble diameters are typically 20-30 μm, some reaching 100-300 μm, producing a slight popping sound when broken.

2. Erosion Resistance Characteristics: Fused silica blocks offer good resistance to erosion by acidic borosilicate glasses. This is because their main component, SiO₂, has good chemical compatibility with acidic borosilicate glasses, minimizing reactions at high temperatures, thus effectively resisting erosion. Their dense structure also hinders glass melt penetration, further enhancing resistance. Thermally, they have a low linear expansion coefficient (only 0.55×10⁻⁶/°C from 0-1000°C), resulting in low thermal stress during temperature changes and good thermal shock resistance. They also have relatively high thermal conductivity, with increased radiative heat transfer through the glassy phase at high temperatures.

3. Specific Applications: Due to their erosion resistance advantage against acidic borosilicate glasses, fused silica blocks are mainly used for constructing sidewalls in acidic borosilicate glass furnaces, effectively resisting melt erosion, ensuring structural integrity and stability, and thus guaranteeing normal production. They are also used in places like thermocouple port blocks in the combustion space, where their thermal properties and chemical stability meet operational requirements.

(IV) Brief Description of Other Refractory Blocks

1. Silica Blocks: Silica blocks are acidic refractories whose main mineral phases are tridymite and cristobalite. They have a high load softening temperature range (1640-1680°C), close to the melting points of tridymite and cristobalite (1670°C, 1713°C). High-quality silica blocks are characterized by high purity and density, high refractoriness under load, low reheating shrinkage, good high-temperature creep resistance, high cold crushing strength, rational mineral phase composition, low true density, and precise dimensions. However, with the trend towards larger photovoltaic glass furnaces and higher melting temperatures, silica blocks face limitations in melting end crown applications due to relatively lower refractoriness (1690-1730°C) and poor thermal shock resistance (1-4 cycles, water quench test). However, they are still applicable to the upper structure of the cooling section due to their high-temperature performance and acidic nature. In glass furnaces, silica blocks are also commonly used in flue areas, withstanding the scouring of hot gases and some chemical erosion.

2. Fireclay Blocks: Fireclay blocks are slightly acidic refractories, their acidity decreasing with increasing Al₂O₃ content. They have the lowest thermal conductivity among common refractories, providing some insulation. Although their refractoriness can be as high as 1700°C, their load softening temperature is only around 1300°C, and under significant R₂O (e.g., Na₂O, K₂O) erosion, it can drop to about 1050°C, so they cannot bear heavy loads at high temperatures. However, their thermal expansion rate is relatively small among common refractories, and due to fine crystals, small and evenly distributed pores, stress is easily buffered, giving them strong thermal shock resistance over a wide range. Based on these properties, fireclay blocks are often used in less critical glass furnace areas, such as flues, where they can work stably under frequent temperature changes.

3. High-Alumina Blocks: Aluminosilicate refractory materials with Al₂O₃ content greater than 48% are collectively called high-alumina refractories. They are graded based on Al₂O₃ content: Grade I, Al₂O₃ >75%; Grade II, Al₂O₃ 60%-75%; Grade III, Al₂O₃ 48%-60%. For Al₂O₃ content below 71.8%, increasing Al₂O₃ increases the primary mullite phase; above 71.8%, mullite decreases while corundum increases, and refractory properties generally improve with increasing Al₂O₃. Compared to fireclay blocks, high-alumina blocks have the distinct advantages of higher refractoriness and load softening temperature, and higher thermal conductivity. Their thermal shock resistance is intermediate between fireclay and silica products. In glass furnaces, high-alumina blocks are used in regenerators, as well as refractory components in the working end, forehearths, and feeders, such as stirrers, distributors, and plungers, leveraging their high-temperature resistance and abrasion resistance.

3. Case Studies of Different Refractory blocks in Glass Furnace Sidewall Applications

Case 1: Large Float Glass Furnace

A large float glass furnace with a melting area of 400 m² and a daily pull of 1000 tons of glass melt is a typical large glass furnace in the float glass sector. Its sidewall conditions are extremely harsh: glass melt temperature consistently maintained at 1500-1550°C, flow velocity varying by area, averaging 0.5-1.0 m/s. Near the hot spot in the melting end, temperatures exceed 1550°C with faster flow (~1.0-1.5 m/s), subjecting the sidewalls to both severe chemical erosion and intense mechanical scouring. Additionally, the high temperature and chemical atmosphere of the combustion space (flame temps ~1600°C, containing alkaline gases/dust) also affect the sidewalls, accelerating erosion.

To address these conditions, the sidewalls utilized fused cast AZS blocks (AZS33# and AZS41#). AZS33# was chosen for its good cost-performance and broad applicability. Its dense microstructure provides good erosion resistance and minimizes stone defects, meeting basic requirements for most sidewall areas, effectively resisting erosion and ensuring glass quality. Its relatively reasonable price helps control costs. For critical high-erosion areas like corners and the throat, AZS41# was selected. AZS41#, with more uniformly distributed ZrO₂ crystals alongside the alumina-silica eutectic, offers the highest erosion resistance within the AZS system, enabling it to withstand severe scouring and erosion in these key areas, ensuring overall glass furnace stability.

During operation, the AZS blocks performed excellently. AZS33# in standard areas showed an average annual erosion rate of 5-8 mm, maintaining stable performance throughout the campaign with minimal glass contamination, ensuring high-quality production. AZS41# performed even better in critical areas: despite the severe conditions in corners and the throat, the annual erosion rate was controlled at 10-15 mm, effectively extending the service life of these parts. This reduced the frequency of shutdowns for repairs, improved productivity, and lowered costs. Through rational selection and use of AZS blocks, this large float glass furnace achieved a service life of 8-10 years, leading the industry.

Case 2: Special Glass Furnace

A special glass furnace dedicated to producing high-purity, high-performance specialty optical glass demands extremely low impurity content and high internal homogeneity. The sidewalls face unique conditions: glass melt temperatures of 1600-1700°C, complex composition including various rare metal oxides and special additives like tantalum oxide (Ta₂O₅) and niobium oxide (Nb₂O₅). These components increase chemical erosiveness, demanding higher chemical erosion resistance from the blocks. Furthermore, the strict quality requirements necessitate that sidewall blocks impart no contamination to the glass melt, which could otherwise affect optical and other physical properties.

To meet these special needs, the sidewalls employed fused cast alumina blocks. Composed primarily of 92%-94% Al₂O₃ corundum phase, these blocks exhibit extremely high resistance to glass penetration and virtually no contamination, fulfilling the purity requirements for specialty optical glass. Their high-temperature performance is excellent: high refractoriness, stable physical/chemical properties at 1600-1700°C, good high-temperature structural strength to withstand mechanical loads and thermal stress without softening, deformation, or melting. Their thermal shock resistance is also adequate to handle temperature fluctuations during start-up, shutdown, and production.

In practice, the fused cast alumina blocks demonstrated outstanding performance. Throughout the campaign, contamination was negligible, producing optical glass with excellent homogeneity and stable optical properties, meeting stringent demands for high-end optics. Under combined high temperature and chemical erosion, the erosion rate was low, averaging 3-5 mm per year, ensuring sidewall structural integrity and stability, enabling long-term stable operation and reliable continuous production. After adopting fused cast alumina blocks, the product qualification rate significantly increased to over 95%, and production efficiency markedly improved.

4. Principles and Methods for Selecting Refractory Blocks for Glass Furnace Sidewalls

(I) Selection Based on Glass Furnace Design and Production Requirements

Glass Furnace design and production requirements are the primary basis for selection, requiring consideration of multiple factors. The designed glass furnace campaign life is a key consideration, dictating different requirements for block longevity and durability. For large glass furnaces with long campaigns (e.g., 8-10 years), durable blocks with strong erosion and wear resistance, like fused cast AZS blocks, are needed to maintain performance under prolonged high temperature, chemical erosion, and mechanical scouring, ensuring stability throughout the campaign.

The type and volume of glass produced also significantly influence selection. Different glass types have varying chemical compositions and processes, leading to different erosion mechanisms and degrees. For specialty optical glass, requiring extreme purity and homogeneity, non-contaminating blocks like fused cast alumina are essential. For high-volume container or float glass furnaces, cost-effectiveness is also considered alongside performance; blocks like AZS33# offer a good balance, meeting requirements in most areas at a reasonable price, aiding cost control.

Selection must also be targeted based on temperature distribution and operating conditions in different glass furnace zones. In the melting end, with the highest temperatures and strongest erosion/scouring, blocks with high temperature resistance, erosion, and abrasion resistance are needed, e.g., AZS41# for critical areas like corners and the throat. In the working end, where temperatures are lower and performance demands reduced, more cost-effective blocks like high-alumina blocks can be used. Glass furnace atmosphere, pressure, and other factors affecting block stability must also be considered.

(II) Consideration of Economic Rationality

Economic rationality is a crucial factor, requiring a balance between block price, service life, maintenance costs, etc. block price directly impacts initial construction cost, varying significantly by material and performance. For instance, fused cast AZS blocks are relatively expensive due to complex production and high raw material costs, whereas fireclay blocks are cheaper. However, selecting lower-quality blocks solely based on price can lead to shorter glass furnace life, frequent repairs, and increased overall costs.

Block service life is a key economic factor. Longer-lasting blocks, though initially more expensive, can reduce replacement frequency, downtime for repairs, and associated production losses over the glass furnace‘s life, potentially lowering total cost. For example, a float glass furnace using high-quality AZS blocks might have an 8-10 year life with higher initial investment, whereas poorer quality blocks might require replacement in 3-5 years, increasing replacement costs and causing significant production losses during downtime.

Maintenance cost is another aspect. Some blocks require frequent maintenance like patching or partial replacement, increasing costs and labor. High-performance blocks typically have lower maintenance needs. For instance, fused cast alumina blocks, with their stable structure and good erosion resistance, require less maintenance compared to ordinary blocks prone to erosion and damage. Therefore, maintenance costs should be integrated into the selection to minimize operating expenses.

Achieving economic rationality while meeting performance requirements necessitates comprehensive cost-benefit analysis. Cost models incorporating purchase cost, service life, maintenance costs, and production losses from downtime can compare different block types. Negotiating with suppliers for better prices and after-sales service can further reduce costs.

(III) Avoiding Adverse Reactions Between Materials

Avoiding adverse reactions between different refractory materials in the sidewall is critical. Different block types can react chemically at high temperatures, forming low-melting-point compounds, degrading performance, accelerating erosion/damage, and severely impacting glass furnace life. For example, contact between acidic blocks (e.g., silica) and basic blocks (e.g., magnesia) at high temperatures can generate low-melting silicates and forsterite, reducing refractoriness and structural strength.

To prevent this, the chemical properties and compatibility of different refractories must be thoroughly understood during selection. Direct contact between chemically incompatible blocks should be avoided. If different materials are necessary due to design or process, transition blocks or layers should be used. These buffer the chemical interaction, reducing its intensity and protecting the main blocks. The transition material should be chemically stable and compatible with both main blocks. For instance, between acidic and basic blocks, a high-alumina transition block can be used, as it is relatively stable and offers good compatibility with both types, effectively minimizing reactions.

Furthermore, when using mortars for laying blocks, compatibility between mortar and blocks must be considered. blocks of different materials should use mortars of matching composition to ensure sealing integrity and stability, preventing reactions that could affect construction quality and glass furnace operation. In summary, avoiding adverse material interactions is a key principle. Proper material selection and structural design can minimize these reactions, extend glass furnace life, and improve efficiency.

5. Conclusion

The selection of refractory blocks for glass furnace sidewalls is crucial for the glass industry, directly impacting glass furnace service life, product quality, production cost, and efficiency. Selection requires comprehensive consideration of key factors including high-temperature performance requirements, chemical erosion resistance, mechanical scouring resistance, and thermal shock adaptation. These interrelated factors collectively influence block performance in the harsh glass furnace environment.

Common suitable block types are diverse, such as fused cast AZS, fused cast alumina, silica, fireclay, and high-alumina blocks, each with unique composition, properties, and applications. Fused cast AZS blocks, with their exceptional glass melt erosion resistance, good thermal shock resistance, and high-temperature stability, are widely used. Fused cast alumina blocks, with their extreme resistance to penetration and non-contaminating nature, play key roles in high-purity specialty glass. Silica blocks offer good resistance to acidic borosilicate glasses and are used for those specific sidewalls.

Case studies of different blocks in actual glass furnaces validate the importance of selecting appropriate blocks based on specific operating conditions and production needs. Rational selection can effectively enhance glass furnace life and productivity while ensuring glass quality. Selection principles include basing choices on glass furnace design and production requirements, considering economic rationality, and avoiding adverse reactions between materials. This involves selecting performance-matched blocks according to designed campaign life, glass type, pull rate, and zonal conditions; achieving economic balance by weighing price, service life, and maintenance costs; and understanding chemical properties and compatibilities to prevent adverse interactions.

With the evolving glass industry, sidewall refractory blocks are trending towards performance enhancement, environmental/energy efficiency, and new material exploration. Future blocks will feature stronger erosion resistance, better thermal shock resistance, and higher high-temperature strength. Simultaneously, meeting environmental standards by reducing harmful emissions and developing energy-efficient insulating blocks is imperative. Exploring new materials like nanomaterials, composites, and smart materials presents new opportunities. Paying attention to these trends and continuously promoting innovation in refractory technology is essential for advancing the glass production industry as a whole.

Henan SNR Refractory Co., Ltd. is dedicated to the manufacture, research and development of fused cast AZS refractory blocks and bonded refractory materials for the glass industry. Meanwhile, SNR can provide total solutions and services for glass furnace design, glass furnace construction, renovation, and upgrading. Please contact me if you have any requirements.

zoe@snrefractory.com/ WhatsApp:+86 15670323812