In glass factories, the primary energy-consuming component is the glass furnace (accounting for over 75% of total energy consumption). Therefore, prioritizing energy conservation in glass furnaces is urgent. Over the past few years, we have implemented numerous energy-saving measures in areas such as glass batch formulation, feeding systems, combustion systems, furnace structure, furnace insulation, waste heat recovery, and operational control, achieving significant results. Many factories have seen notable reductions in fuel consumption indicators, with some even reaching first-class or exceptional furnace standards. However, compared to international levels, there remains a considerable gap. Thus, further efforts are needed to reduce energy consumption. Below are several proposed energy-saving approaches:

1.Increasing Glass Melt Temperature Without Raising Flame Temperature

2.Shallow Refining, Deep Extraction, and Controlling Unidirectional Melt Flow

5.Reduction of Waste Heat Loss

6.Optimization of Usable Heat Utilization

7.Optimization of Batch Formulation and Pelletization Technology

8.Strategic Application of Advanced Refractory Materials

9.Comprehensive Energy Conservation Strategy

1. Increasing Glass Melt Temperature Without Raising Flame Temperature

Raising the temperature of the glass melt accelerates melting speed, shortens melting time, increases production, and reduces unit energy consumption. Specific methods include:

(1) Enhancing Radiative Heat Transfer from the Combustion Space to the Glass Melt

The glass melt selectively absorbs radiant energy. Radiation with wavelengths below 3 μm penetrates the surface and transfers downward. Sources emitting such short-wavelength radiation include carbon particles in the flame and the inner surfaces of the furnace walls. Therefore, increasing the flame‘s emissivity (through oxygen-deficient combustion or carbon-enhancing measures) and maintaining high emissivity of the refractory materials (related to surface roughness and temperature) can enhance radiative heat transfer.

For example, the emissivity of fireclay and silica bricks at high temperatures is:

0.61–0.62 at 1000°C

0.52–0.53 at 1200°C

0.47–0.49 at 1400°C

The emissivity of fused-cast refractories at high temperatures is 0.4–0.5.

Eliminating the "cold gas" layer near the melt surface.

Attention should be paid to the height of the port floor above the melt and the flame projection angle.

Oxygen-assisted melting can also be considered (e.g., injecting oxygen at 195–500 m/s, as done abroad, increases heat transfer rates and raises flame temperature near the melt surface by about 100°C).

(2) Improving Temperature Uniformity in the Glass Melt

The goal is to enhance heat transfer by reducing the surface temperature of the melt, thereby improving temperature uniformity along the depth of the tank. Measures to achieve this include:

Increasing tank depth to strengthen vertical convection and improve temperature uniformity, while also accommodating higher melting rates.

Furnace insulation.

Electric boosting.

2. Shallow Refining, Deep Extraction, and Controlling Unidirectional Melt Flow

This approach aims to increase the temperature in the refining zone, reduce backflow, and ensure high-quality glass enters the throat. This improves yield, quality, and minimizes energy losses from recirculating melt. Key measures include:

Installing low and wide weirs to create shallow refining zones.

Using submerged throats (though not necessary for dark-colored glass).

Most factories report that homogenization is a critical factor affecting product quality. Currently, homogenization often suffers from inherent deficiencies and poor control. The initial uniformity of the batch is compromised upon charging, and uneven heat distribution due to furnace heat loss leads to thermal inhomogeneity. Relying solely on natural diffusion is insufficient, necessitating forced homogenization. Effective measures include:

Bottom bubbling (especially effective for dark glass).

Forehearth stirring (proper positioning, depth, and technique are crucial; current domestic stirrer materials need improvement).

Surface skimming (enhances lateral flow, improves temperature uniformity, and removes scum and crust).

Forehearth bottom discharge (via controlled leakage holes, either continuous or intermittent).

Electric heating in the forehearth (improves vertical temperature uniformity but may not always enhance horizontal uniformity; electrode design, resistance control, and maintenance must be carefully managed).

While forced homogenization is essential, natural diffusion should still be leveraged. Therefore, careful consideration must be given to the size of the working end and the length of the forehearth during design.

By implementing these approaches, further energy savings can be achieved, bringing domestic glass production closer to international standards.

4. Stable Batch Feeding System

The stability of gob shape, size and temperature is the fundamental prerequisite for ensuring forming quality and production efficiency. The degree of separation between the forehearth and working end, along with the forehearth‘s cross-sectional design, dimensions, insulation conditions, heating and cooling systems constitute the primary factors influencing feeding stability. Implementing complete separation between forehearth and working end enables the forehearth to maintain an independent operating regime free from external disturbances. The practice adopted by some factories of relying on heat from the melting zone to warm the forehearth without complete separation is

indeed questionable from an energy efficiency perspective.

The adoption of saddle-shaped cross-section at the forehearth bottom has proven effective in minimizing transverse temperature differentials. Proper deepening of the spout can increase hydrostatic pressure, thereby enhancing temperature stability of the gobs. The length and width of forehearth should be carefully determined based on glass flow rate and production capacity, with slightly extended forehearth length being advantageous for temperature regulation and better accommodation of flow variations.

Particular attention must be paid to thermal insulation due to significant heat dissipation, especially in the spout area. The heating and cooling systems should provide flexible and reliable temperature control while maintaining thermal uniformity throughout the glass melt. In this configuration, the cooling system serves for coarse adjustment while the heating system provides fine-tuning. The combined system incorporating multi-nozzle gas heating with electric heating is widely regarded as the optimal solution for precise temperature control.

5. Reduction of Waste Heat Loss

(1) Minimization of Unrecoverable Heat Loss

This category includes heat dissipation through furnace surfaces, radiation losses from various openings, and heat carried away by gases escaping through ports and brick joints. Several effective countermeasures have been developed:

Furnace insulation technology in China has achieved remarkable results in recent years, though it still represents only the preliminary stage of development.

Future enhancements should focus on:

Implementation of multi-layer composite insulation structures

Application of advanced insulating materials including sandwich-type and filler-type configurations

Development of lightweight refractory concrete materials

Research and development of high-performance sealing materials compatible with various refractory types

For openings and joints sealing, critical areas requiring special attention include batch charging ports, temperature measurement holes and observation ports. Recommended solutions comprise:

Adoption of fully enclosed feeding systems such as screw-type or Wrap-around type feeders

Utilization of corundum-embedded thermocouples for temperature monitoring

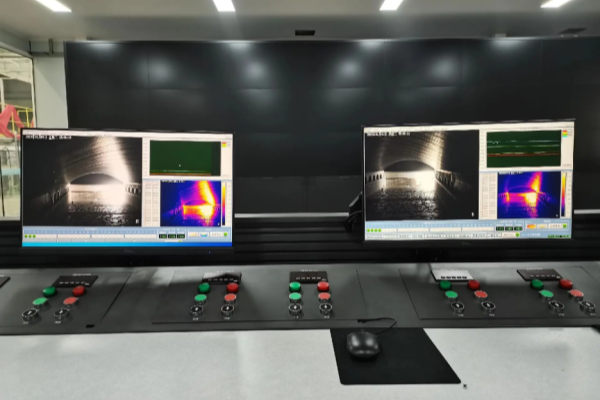

Installation of industrial monitoring systems for flame and melting observation

Furnace scaling represents another important consideration, as larger furnace capacities demonstrate lower heat loss per unit of production output.

(2) Reduction of Heat Loss from Recirculation

The energy consumed in reheating recirculated glass melt typically accounts for approximately 10% of total melting energy consumption. Effective solutions to address this issue include:

Strategic installation of weirs to control backflow patterns

Implementation of submerged throat configurations (with height adjustments based on glass color requirements)

Optimization of glass temperature before entering the throat area

6. Optimization of Usable Heat Utilization

(1) Ensuring Complete Fuel Combustion

For oil-fired furnaces, key optimization measures involve:

Selection of high-efficiency atomizing nozzles including domestic GNB internal-mix nozzles and imported mechanical/medium-assisted composite nozzles from Japan, the U.S. and Germany

Implementation of enhanced atomization techniques

Customized design of port and breastwall configurations to optimize flame distribution

For gas-fired furnaces, critical parameters include:

Precise control of air-to-gas momentum ratio

Optimization of combustion aerodynamics to ensure proper air envelopment of gas streams

(2) Enhancement of Heat Exchange Efficiency

To maximize air preheating temperatures, several technical approaches have proven effective:

Expansion of regenerator surface area through increased checkerwork height

Innovation in checker brick design including cross-shaped and cylindrical configurations

Optimization of checkerwork patterns such as basket-weave or chimney-style arrangements

Research efforts should focus on:

Advanced checker brick materials development

Improvement of gas flow distribution uniformity within checkerworks, which directly impacts heat exchange efficiency

Investigation of key parameters including checkerwork construction coefficient and volume ratio between upper/lower flues and checkerwork

(3) Waste Heat Recovery from Flue Gas

Modern glass plants employ various waste heat recovery strategies:

Installation of waste heat boilers in exhaust systems

Application of heat pipe technology for additional heat recovery

Ongoing research into utilizing flue gas heat for raw material preheating and sintering processes

7. Optimization of Batch Formulation and Pelletization Technology

(1) Modification of Batch Composition

The strategic incorporation of small quantities of fluxing components such as lepidolite into the batch formulation represents a significant advancement in glass melting technology. These additives serve to effectively lower the melting temperature of glass while simultaneously accelerating the melting process. The practical benefits of this approach have been demonstrated through measurable increases in production output, with some operations reporting yield improvements of 15-20%. The mechanism involves the reduction of glass viscosity at lower temperatures, which enhances heat transfer efficiency and promotes faster dissolution of batch materials. Careful consideration must be given to the selection and proportioning of these fluxing agents to avoid compromising the final glass quality or causing undue refractory wear.

(2) Advanced Batch Pelletization Technology

The development of dry-process pelletization technology without binders has emerged as a breakthrough in batch preparation methods. This innovative approach transforms conventional powdered batch materials into uniform spherical pellets through specialized compaction techniques. The advantages of this method are manifold:

Significant reduction of dust generation both inside and outside the furnace

Acceleration of solid-state reactions due to improved particle contact

Enhancement of heat transfer through increased surface area exposure to the melt

Improvement of batch homogeneity and consistency

Field applications have demonstrated that pelletized batch can reduce melting time by 8-12% while simultaneously extending furnace campaign life. The elimination of binder materials not only reduces costs but also prevents the introduction of undesirable impurities into the glass composition. Ongoing research focuses on optimizing pellet size distribution and mechanical strength to further improve melting performance.

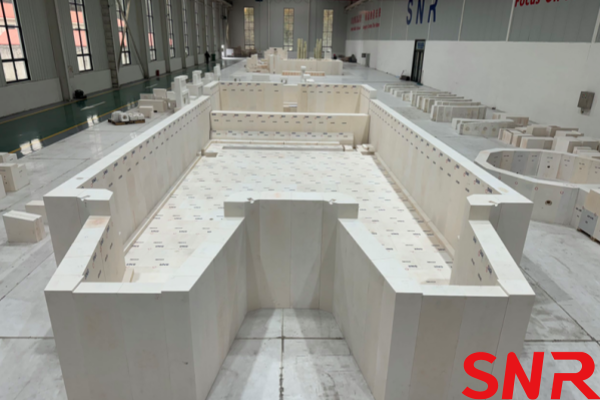

8. Strategic Application of Advanced Refractory Materials

The selection and configuration of high-performance refractory materials has become a critical factor in modern glass furnace design and operation. Current best practices emphasize the comprehensive use of premium refractory products including:

Electrically fused cast materials for critical zones

Zirconia-based, chrome-based, and alumina-based compositions

Spinel and basic refractory formulations

High-density, high-strength specialty products

The implementation of these materials requires careful system engineering to ensure balanced wear characteristics throughout the furnace structure. Proper material pairing in different furnace zones can synchronize the service life of all components, thereby avoiding premature failures that necessitate partial repairs.

The quality of refractory materials profoundly impacts several key operational parameters:

Furnace productivity and output capacity

Glass quality and defect levels

Specific energy consumption

Overall campaign duration

Addressing these deficiencies requires urgent attention through:

Intensified domestic research and development

Strategic technology partnerships

Enhanced quality control protocols

From a long-term perspective, increased investment in premium refractory materials proves economically justified through:

Extended furnace campaigns

Reduced maintenance downtime

Improved energy efficiency

Enhanced product quality

The expansion of high-grade refractory applications to additional furnace zones represents a worthwhile direction for future development. This includes the evaluation of novel material combinations and the development of customized solutions for specific operating conditions.

9. Comprehensive Energy Conservation Strategy

Effective energy management in glass furnace operations demands a holistic, systems-based approach that integrates multiple synergistic measures to achieve optimal performance. Key focus areas include thermal efficiency enhancement through optimization of flame radiation characteristics, advanced furnace insulation systems, and precision bubble technology for improved convection. Process intensification is achieved via shallow refining zone configurations, deep glass withdrawal techniques, and active homogenization methods, while heat loss mitigation relies on enhanced sealing technologies, strategic furnace scaling, and sophisticated waste heat recovery systems.

Innovations in raw material processing, such as pelletized batch systems, optimized batch formulations, and alternative material sources, further contribute to energy savings. Additionally, refractory system optimization—through material performance matching, wear pattern management, and life cycle optimization—plays a crucial role in sustaining long-term efficiency.

Successful implementation of these strategies requires coordinated efforts across multiple disciplines, including process engineering, materials science, combustion technology, and automation and control systems. Continuous improvement should be pursued through systematic benchmarking against international standards, adaptive implementation of proven technologies, and the development of customized solutions tailored to local conditions. Establishing comprehensive performance monitoring systems ensures ongoing optimization and accountability.

This integrated approach not only reduces production costs but also enhances environmental sustainability by minimizing the carbon footprint of glass manufacturing. Moving forward, the industry must strike a balance between technological innovation and practical implementation, carefully weighing both economic viability and technical feasibility to achieve sustainable energy conservation in glass melting operations.

Henan SNR Refractory Co., Ltd. has been specializing in the production of fused cast AZS blocks for about 25 years. We use high-quality raw materials and advanced fusion technology to provide customers with high-quality products. From raw material procurement to finished product delivery, every step is strictly quality inspected to ensure that every indicator meets the standards, so you can use it with confidence.

If you have any needs, you can contact me at any time.

If you have any needs, you can contact me at any time.

Web: www.snr-azs.com

Email:wendy@snrefractory.com