Introduction

Container glass is widely used in industries such as food, beverage, and pharmaceuticals, serving as an important material in the packaging sector. The advancement of its production technology is crucial for improving quality, reducing costs, and enhancing production efficiency. The furnace is the core equipment in container glass production, and the full electric melting technology—which utilizes electrical energy as the heat source to achieve glass melting—represents an advanced approach. Compared to traditional flame melting technology, it offers advantages such as high energy utilization efficiency, low environmental pollution, and superior glass melt quality. Traditional furnaces have certain limitations in energy consumption and environmental impact, making the full electric melting furnace, as a new furnace technology, a source of new opportunities and transformation for container glass production.

1. Working Principle of Full Electric Melting Furnace

2. Advantages of Full Electric Melting Furnace in Container Glass Production

3. Application of Full Electric Melting Furnace in Opal Glass Production

4. Main Issues and Countermeasures of Full Electric Melting Furnace in Container Glass

Production

1. Working Principle of Full Electric Melting Furnace

The full electric melting furnace operates based on the principle of electric melting. By installing special electrode structures inside the furnace, an alternating electric field is generated within the glass melt when alternating current passes through the electrodes. The glass melt possesses a certain degree of electrical conductivity, and under the influence of the alternating electric field, ions inside move directionally and generate friction, thereby producing Joule heat to achieve heating and melting of the glass. This heating method fundamentally differs from traditional flame heating, enabling precise control over the heating of the glass melt.

The high-temperature melting of glass batch in a full electric melting furnace relies on ionic conductive heating. Monovalent metal ions such as potassium and sodium in the glass composition play a conductive role. Its conductive mechanism differs from metallic conduction, with the characteristic that conductivity increases as the temperature of the melt rises. The relationship between conductive resistance and melt temperature exhibits the following features:

① All glass compositions exhibit negative resistance characteristics with increasing temperature;

② Due to differences in glass composition, the conductive resistivity of glass melts varies significantly, and the slope of change with temperature also differs. Glass is an insulator at low temperatures but becomes conductive in its molten state at high temperatures due to the presence of alkali metal ions such as sodium and potassium. By arranging electrodes at different positions in the furnace, current is passed through the glass melt inside the furnace, utilizing the Joule heating effect to generate heat and achieve the transformation from glass batch to liquid. The entire process can be controlled by adjusting the input electrical power to regulate the melting temperature.

2.1 Structural Features

(1) The electrode system is delicately designed, requiring special materials that are resistant to high temperatures and corrosion. The arrangement of electrodes is optimized to ensure uniform distribution of the electric field within the glass melt, facilitating even heating of the glass liquid.

(2) Excellent thermal insulation is achieved through the use of high-performance insulation materials, effectively reducing heat loss from the furnace surface.

(3) High level of automation control enables real-time monitoring and adjustment of key parameters such as temperature and electric field strength within the furnace. This allows for precise control, ensuring that the glass melt undergoes melting and forming under optimal process conditions, thereby enhancing the stability of product quality.

2.2 Energy Efficiency

Traditional flame furnaces rely on surface heating through flames, resulting in significant heat loss through exhaust gases and low thermal utilization efficiency. In contrast, full electric melting furnaces generate heat directly within the glass melt. The space above the glass melt surface maintains a cold-top structure with temperatures below 150°C. Energy is primarily consumed in the glass melting process and heat dissipation through the furnace walls, with no heat loss due to exhaust gases. Since heat is directly applied to the glass melt, energy utilization efficiency is greatly improved, with thermal efficiency potentially increasing by 30% to 60% compared to traditional flame furnaces.

2.3 Environmental Cleanliness

Full electric melting furnaces involve no combustion process, thereby eliminating pollutants such as nitrogen oxides, sulfur compounds, and smoke dust. This reduces the emission of "industrial three wastes" and improves the production environment. Particularly in the production of opal glass, the volatilization of fluorides decreases from 30% to 50% in traditional flame furnaces to 5% to 8% in full electric melting furnaces, significantly reducing fluoride pollution and helping production enterprises lower pollution control costs.

2.4 High Product Quality

The use of full electric melting furnaces reduces contamination and discoloration of the glass melt caused by gas combustion. Since the electric field is uniformly distributed within the glass melt, each part of the melt is heated evenly, minimizing temperature gradients. This helps reduce internal stress in the glass, improving optical uniformity and consistency in physical properties. At different production stages, heating power can be quickly and accurately adjusted, avoiding production instability due to temperature fluctuations and reducing defects such as bubbles and stones. Container glass produced by full electric melting furnaces exhibits high transparency, excellent strength, and high rates of product qualification and premium quality, meeting the requirements of high-end packaging products such as high-white cooking wine bottles and premium cosmetic bottles, where quality advantages are particularly evident.

2.5 Small Footprint

The furnace structure of full electric melting furnaces is simple, featuring vertical melting with deeper melting pools compared to traditional flame furnaces. They do not require extensive combustion systems, waste heat recovery systems, or dust emission control systems, resulting in a significantly reduced footprint.

3. Application of Full Electric Melting Furnace in Opal Glass Production

3.1 Development and Application of Opal Glass Furnace

Opal glass is formed through the opacifying effect of fluorides such as sodium fluorosilicate and fluorite. During the forming process, the glass liquid gradually becomes opaque, exhibiting opalescent characteristics. Since fluorides are highly volatile in flame furnaces, the volatilized components not only affect glass quality and cause raw material loss but also severely pollute the environment. Using full electric melting furnaces for opal glass production can reduce pollution and improve environmental benefits.

3.2 Furnace Structure

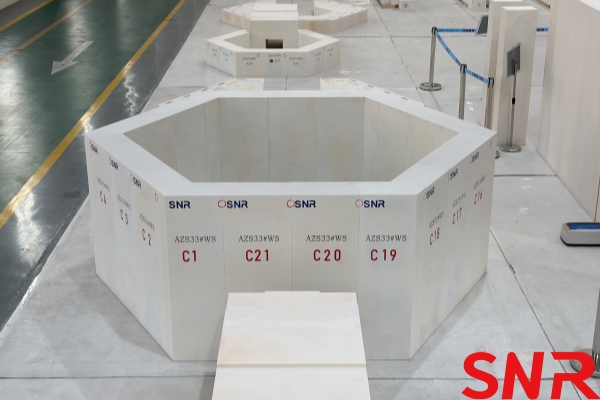

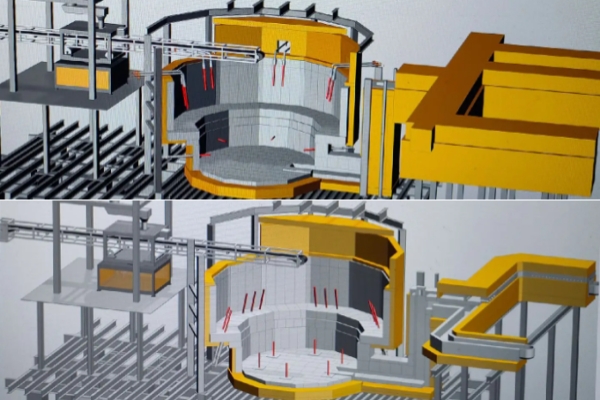

Full electric glass melting furnaces are designed based on factors such as glass type, production scale, process requirements, and site conditions. Common structures include rectangular, hexagonal, or polygonal furnace bodies. Hexagonal or polygonal furnace structures are more complex and costly but can reduce heat dissipation from the furnace surface. During glass melting, dead zones are minimized, facilitating uniform melting and enabling symmetrical electrode arrangement to achieve three-phase balanced power supply. Therefore, designing hexagonal or polygonal structures offers significant advantages.

The furnace roof structure and feeding method of full electric melting furnaces differ from traditional flame furnaces. The batch must be evenly spread in a thin layer from top to bottom on the glass surface, forming what is known as the batch layer. A mobile belt feeder is used to distribute the batch evenly across the furnace plane, and the furnace crown can adopt a flat arch design.

The selection of refractory materials for full electric melting furnaces should focus on the crown and tank walls.

(1) During furnace heating, flame heating is required to reach the high temperatures needed for glass melting, while during normal production, the crown space temperature must drop below 150°C. Therefore, the refractory materials for the crown must possess excellent resistance to thermal shock.

(2) Due to the need for holes in refractory bricks for horizontal electrode insertion, the temperature near the electrodes is relatively high. Opal glass, with its high fluoride content, is highly corrosive to the tank walls. Additionally, the convective flow of glass liquid induced by electrodes is several times faster than in traditional flame furnaces, accelerating the erosion of refractory materials near the electrodes. Therefore, the refractory materials for the tank walls must exhibit excellent high-temperature resistance and corrosion resistance, typically requiring the use of high-zirconia, shrinkage-free AZS bricks.

3.3 Electrode Arrangement

The electrodes in the melting section provide energy for glass melting. They are evenly distributed around the furnace and inserted horizontally in three layers, following a flat insertion method. The power of the electrodes must be reasonably set to ensure the furnace maintains a cold-top state during glass melting and meets the requirements for deep vertical melting. Electrodes in other parts of the furnace are arranged based on process requirements, primarily using the flat insertion method.

In recent years, molybdenum electrodes have been widely applied and developed in glass electric melting technology. Their production process involves molybdenum powder → pressing → sintering → pressure processing → inspection and delivery. For a long time, molybdenum electrodes in glass electric melting furnaces have mostly been arranged using "flat insertion" and "bottom insertion" methods. Horizontally arranged molybdenum electrodes are particularly susceptible to bending stress due to their own weight, limiting their insertion depth. Exceeding a certain length increases the risk of breakage. While the "bottom insertion" method offers advantages such as high melting efficiency and the ability for continuous feeding, improper design, installation, or use of the water-cooling jacket to prevent oxidation can easily lead to corrosion of the bottom bricks, with severe cases posing a risk of material leakage. Therefore, neither the "flat insertion" nor "bottom insertion" methods provide an ideal temperature field for the furnace. However, the "top insertion" method for molybdenum electrodes can adjust the energy distribution within the furnace by changing the installation position or electrode shape, creating favorable conditions for glass melting. It also offers significant advantages such as ease of replacement, convenient installation and maintenance, and extended furnace lifespan. Currently, "top insertion" electrodes represent a future development trend.

4. Main Issues and Countermeasures of Full Electric Melting Furnace in Container Glass Production

4.1 Electrode Lifespan Issue

Electrodes must combine high conductivity, resistance to high temperatures and corrosion, and must not contaminate the glass liquid. However, the selection of materials meeting these requirements is limited. High-performance electrodes are costly, while low-cost electrodes often fail to meet long-term stable operation demands.

In high-temperature, high-electric-field, and corrosive glass liquid environments, electrodes are prone to chemical corrosion, especially from fluorides in opal glass production. For example, molybdenum electrodes in alkali-containing glass liquids undergo oxidation and sulfidation, forming loose corrosion layers that degrade performance and shorten lifespan. Frequent electrode replacement not only increases production costs—including material and labor expenses—but also disrupts production, affecting efficiency and increasing defect rates.

Countermeasures:

Develop new corrosion-resistant electrode materials and optimize electrode structure and installation methods to reduce erosion and extend replacement cycles.

4.2 Electrode Arrangement Issue

Electrode arrangement directly affects the uniformity of the electric field distribution. Poor design, such as inappropriate spacing or suboptimal shapes, can lead to uneven heating of the glass liquid, causing localized overheating or undercooling. This results in internal stress, reduced strength and optical performance, and increased defects such as bubbles and stones.

Countermeasures:

Conduct thorough feasibility studies during design to ensure scientific and reasonable electrode arrangements that meet the requirements for high-quality container glass production.

4.3 Power Supply Stability Issue

Full electric melting furnaces have high electricity consumption and require extremely stable power supply. Voltage fluctuations or brief power outages can cause unstable melting temperatures, electrode overheating or melting, and even solidification of the glass liquid, damaging equipment. In regions with high electricity prices or unstable power supply, production costs and operational risks increase significantly.

Countermeasures:

Strictly assess local power conditions before construction and, if necessary, equip the system with voltage stabilizers or backup power supplies.

4.4 High Investment Costs

Full electric melting technology involves complex equipment, with high costs for research and development, manufacturing, and installation. Retrofitting existing production lines requires significant investment, and due to equipment variations, standardization of retrofit solutions is challenging, leading some enterprises to hesitate due to investment risks.

Countermeasures:

As the technology is promoted and economies of scale are achieved, equipment costs are expected to gradually decrease. Enterprises should comprehensively evaluate long-term benefits and plan investments rationally.

4.5 Shortage of Technical Talent

As a new technology, full electric melting lacks sufficient professional talent. The shortage of skilled operators and maintenance personnel affects production stability, equipment efficiency, and process optimization.

Countermeasures:

Strengthen cooperation with universities and research institutions to develop specialized training programs. Cultivate interdisciplinary talent proficient in both glass production processes and full electric melting technology. Additionally, enhance internal technical exchanges and training within enterprises.

4.6 Process Adaptability Needs Improvement

Different glass compositions require varying electric melting process parameters, such as electric field strength and heating power. Currently, research on full electric melting processes for diverse glass compositions is not systematic, and mature standards are lacking. Some special glass types may not be stably produced using this technology.

Countermeasures:

Deepen research on full electric melting processes, accumulate production data and experience, and gradually expand its application to the production of various glass types.

Full electric melting furnaces offer significant advantages in container glass production, with substantial improvements in energy utilization efficiency, product quality, and environmental performance compared to traditional furnaces. However, to achieve widespread application, the current challenges must be properly addressed. In terms of electrodes, increased research and development investment is needed to explore new electrode materials and optimize electrode arrangement designs. For energy supply, cooperation with power departments should be strengthened to ensure stable power supply while improving energy utilization efficiency and reducing electricity costs. In the field of technology and processes, in-depth research should be conducted on adaptive processes for different glass compositions to enhance compatibility with existing equipment. In talent cultivation, education and training systems should be improved to develop more professionals. Through continuous technological development and refinement, the widespread application of full electric melting furnaces will drive container glass production toward greater efficiency, quality, and environmental sustainability, making significant contributions to the sustainable development of the packaging industry.

Henan SNR Refractory Co., Ltd. has been specializing in the production of fused cast AZS blocks for more than 25 years. We use high-quality raw materials and advanced fusion and casting technology and equipment to provide customers with high-quality products. From raw material procurement to finished product delivery, every step is strictly quality inspected to ensure that every indicator meets the standards, so you can use it with confidence.

Should you have any inquiries or specific requirements, our team is ready to provide professional support and tailored solutions.