The furnace bottom is the most critical and severely stressed region in a glass melting furnace, enduring long-term static pressure from high-temperature molten glass, complex chemical attack, intense mechanical scouring, and potential thermal stress impacts. Its erosion rate and condition directly determine the furnace campaign life, energy consumption, glass quality stability, and production costs. Bottom erosion is a complex, systemic engineering problem involving coupled multi-physical and multi-chemical processes; optimizing any single factor cannot achieve optimal protection. This article comprehensively analyzes the various erosion causes and their interactions in glass furnace bottoms and proposes an integrated protection strategy encompassing structural optimization, process control, material selection, and construction maintenance.

Ⅰ. Multi-Dimensional In-Depth Analysis of Bottom Erosion Mechanisms

Ⅱ. Building a Systematic, Layered Comprehensive Protection System

Ⅲ. Conclusion and Outlook

Ⅰ. Multi-Dimensional In-Depth Analysis of Bottom Erosion Mechanisms

Bottom erosion is not caused by a single factor but is the inevitable result of intertwined physical, chemical, mechanical, and thermodynamic processes. Understanding the details and interrelationships of these mechanisms is fundamental to formulating effective protective measures.

1.1 Chemical Erosion: Fundamental Damage Based on Thermodynamics and Kinetics

Chemical erosion is the most core and fundamental driving factor for the loss of refractory materials in the furnace bottom. Its essence lies in the heterogeneous chemical reactions between refractory components and the glass melt at high temperatures, governed by thermodynamic equilibrium and kinetic diffusion laws.

Erosion Mechanism Breakdown:

Direct Dissolution Reaction: Strong fluxes in the glass melt (mainly Na₂O, K₂O, as well as B₂O₃, F⁻, etc.) diffuse to the refractory interface and react with acidic or amphoteric oxides (e.g., SiO₂, Al₂O₃) in the material to form new phases with low melting points and high fluidity. For example, in alumina-zirconia-silica (AZS) blocks, Na₂O reacts with Al₂O₃ and SiO₂ to form nepheline (Na₂O·Al₂O₃·2SiO₂, m.p. ~1526°C) or even lower-melting eutectics; for corundum blocks, it forms β-alumina (Na₂O·11Al₂O₃), etc.

Selective Erosion: For multi-phase composite refractories (e.g., AZS), erosion does not proceed uniformly. The glassy phase (primarily silicates) is always preferentially eroded and dissolved, destroying the bonding network of the brick structure, leading to decreased structural strength. Subsequently, primary crystal phases (corundum, baddeleyite) are exposed and detach as particles. The crucial "skeleton" role of baddeleyite (ZrO₂) in AZS blocks stems from its stronger chemical inertness towards alkaline oxides.

Reductive Erosion: In fuel-fired furnaces, if the flame atmosphere or batch contains reducing agents (e.g., CO, C, incompletely burned hydrocarbons), certain higher oxides (e.g., Fe₂O₃, TiO₂) in the refractory may be reduced to lower valence states, significantly lowering their refractoriness and erosion resistance, and potentially altering the melt‘s surface tension, exacerbating erosion.

Manifestation Characteristics: A "altered layer" (or reaction layer) with different viscosity and composition from the bulk glass forms on the hot face of the brick. Under ideal stable conditions, this layer can provide some protective effect. However, if its viscosity is too low or the interface is unstable, it will continuously be washed away by the convective flow of glass, leading to uniform "dissolution thinning" of the brick surface. Microscopically, the brick structure appears loosened, porosity increases, and grain boundaries are destroyed.

1.2 Mechanical scouring and Physical Wear: Material Detachment via Momentum Transfer

Chemical erosion weakens the structural strength of the brick surface, while mechanical scouring completes the final removal of material.

Sources of Scouring Force:

Forced Convection: Generated by active stirring processes such as bubbling, weirs, and electric boosting, producing high-speed, directional liquid flows.

Natural Convection: Driven by density differences caused by temperature variations between the bottom and sidewalls (the bottom is typically cooler), forming continuous circulating flows. The upward flow from the hot spot impacts sidewalls strongly, while the returning cooler, higher-viscosity glass exerts a continuous "dragging" effect on the bottom.

Batch Charging and Glass Discharge Flows: The overall flow trend formed by batch feeding and glass outflow.

Action Mechanism: High-velocity flowing glass applies shear stress to the chemically eroded and weakened surface, directly carrying away reaction products or loosened crystal grains. This is a typical coupled erosion mode of "chemical erosion first, mechanical scouring follows." In localized areas such as around bubbling ports, upstream faces of weirs, and throat inlets, this scouring erosion is particularly intense, often forming directional wear patterns like grooves and pits.

1.3 Upward Drilling and the "Mushroom Stone" Effect: A Unique Destruction Form from Gravity and Convection

This is a severe erosion phenomenon unique to vertical joints, posing a fatal threat to the bottom sealing integrity.

Formation Mechanism:

1.Existence of Joints: Joints (especially longitudinal ones) are inherent weak points.

2.Thermo-Capillary Convection: Gas or low-viscosity melt within the joint is heated and moves upward, transferring heat upwards.

3.Glass Penetration and Selective Flow: Low-viscosity, highly reactive glass is drawn deep into the joint via capillary action. Due to a temperature/viscosity gradient (hotter center, cooler sides), the glass in the joint center, having lower viscosity, continues to flow upward while simultaneously dissolving the side blocks.

4.Self-Perpetuating Enlargement: This upward dissolution-flow cycle sustains and intensifies itself, causing rapid enlargement of the joint‘s upper section, forming an inverted "trumpet" or "mushroom-shaped" cavity. In severe cases, the bottom of overlying paving blocks or sidewall blocks can be hollowed out, causing them to sink or collapse.

1.4 Physical Damage from Thermal and Structural Stress

Thermal Shock Spalling: During furnace startup, shutdown, reversal, or production instability, drastic temperature changes in the bottom generate immense thermal stress within the refractory. Due to the low tensile strength of refractories, when thermal stress exceeds its limit, the brick surface develops network cracks and spalls, exposing fresh surfaces and drastically accelerating chemical erosion.

Static and Dynamic Mechanical Stress:

Static Stress: The enormous static pressure of the glass bath (especially in deep tanks) keeps bottom blocks under long-term compressive stress, potentially accelerating high-temperature creep deformation.

Dynamic Stress: Additional mechanical stresses from uneven foundation settlement, constrained thermal expansion of the steel structure, or pre-stress during brick installation can induce cracks in the blocks, providing fast paths for erosive media.

1.5 Erosion by Batch Dust and Volatile Substances

In the charging end area of the bottom, unmelted batch dust (rich in soda ash, sulfate, etc.) may settle, creating a localized, highly alkaline, and oxidative environment. This causes exceptionally severe "dry" erosion of refractories, with a rate far exceeding that from molten glass erosion.

Ⅱ.Building a Systematic, Layered Comprehensive Protection System

Addressing the above erosion mechanisms requires a systems engineering approach employing multiple strategies and layered defenses, building a system from "passive endurance" to "active protection."

First Level: Optimizing Furnace Structure and Process Design – Reducing Erosion Driving Forces at the Source

Rational Furnace and Tank Depth Design: Avoid excessively deep tanks to reduce static pressure and bottom glass residence time while meeting melting quality requirements. Optimize bottom contours to avoid dead flow zones or excessive turbulence.

Scientific Layout of Bubbling and Electric Boosting: Bubbles should be evenly distributed to avoid concentrated bubble clusters impacting a single point. Bubble pressure and frequency should be optimized to achieve good mixing while minimizing local scouring on the bottom. The arrangement and power distribution of electric boosting electrodes should favor forming a stable thermal barrier and flow pattern.

Strengthen Bottom Insulation and Temperature Uniformity: Good insulation not only saves energy but, more importantly, reduces the vertical temperature gradient in the bottom, thereby weakening the thermo-capillary convection driving upward drilling. Simultaneously, uniform bottom temperature reduces thermal stress and suppresses localized strong convection.

Control Process Stability: Maintaining stable melting temperature, batch line position, furnace pressure, and redox atmosphere, and avoiding large fluctuations in operating conditions, are the foundation for reducing thermal shock and abnormal erosion.

Second Level: Scientific Selection and Structural Combination of Refractories – Constructing a Solid Physical-Chemical Defense Line

This is the core material foundation of the protection system. The selection principle should shift from simply "pursuing high grade" to "matching service conditions, leveraging complementary strengths, and optimizing structure."

1. Selection of Main Layer Refractories

Working Layer (Paving Blocks) in Direct Contact with Glass:

Primary Choice: No-Shrinkage (Dense) Fused Cast AZS Blocks (AZS 33#/36#/41#).

Advantages: Extremely high density (>3.9 g/cm³) and very low porosity (<1%) fundamentally block glass penetration. The robust network formed by the baddeleyite eutectic structure provides excellent erosion andscouring resistance.

Selection Logic:

General Erosion Areas (e.g., most of flat glass furnace bottom): Use AZS 33# or 36# for good cost-performance.

High Erosion Areas (Bubbling zones, throat, charging end corners): No-shrinkage AZS 36# or 41# must be used. Type 41# brick, with the highest ZrO₂ content (>40%), offers the best erosion resistance, especially for demanding environments like ultra-clear or borosilicate glass.

Key Point: Blocks produced by inclined casting or quasi-no-shrinkage technology must be used to ensure the working face is the dense, shrinkage-free zone, preventing exposed shrinkage cavities.

Alternative/Supplementary Options:

α-β/β-Alumina Fused Cast Blocks: Suitable for alkali-free glass fiber furnaces, certain electronic glass furnaces. They offer excellent erosion resistance to alkali-free glass but have slightly lower thermal shock resistance and are more expensive.

Dense Sintered Zircon Blocks: Used in specific areas of soda-lime glass furnace bottoms for their good sodium resistance, but thermal shock resistance is their weakness.

Important Trend: Large-Size, Integrated Paving Blocks. Using the largest possible brick sizes (e.g., long blocks) can maximally reduce the number of longitudinal joints, fundamentally eliminating the primary path for upward drilling. This is a core concept in modern large furnace bottom design.

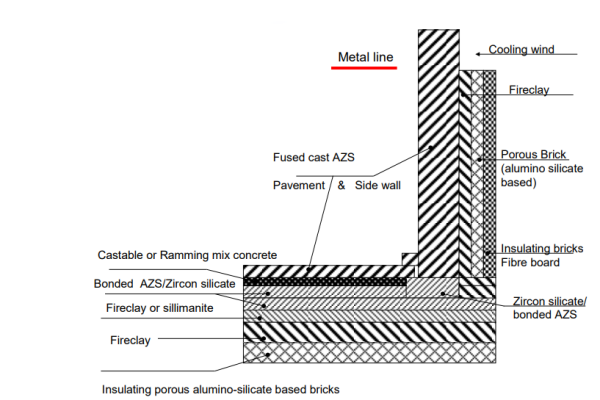

2. Scientific Matching of Sealing and Insulation Layers

Beneath the working layer is a multi-layer structure requiring a balance of sealing, stability, and insulation.

Sealing Layer (Backup Layer):

Materials: Typically dense sintered zircon blocks, high-quality sintered mullite blocks, or dense chrome-alumina blocks.

Functions:

1. Safety Barrier:

If the working layer is accidentally penetrated, this layer can effectively block further glass penetration, buying time for emergency response.

2. Chemical Compatibility:

These materials react more slowly with potentially leaking glass, and the viscous products generated can block channels.

3. Stress Buffer:

Their thermal expansion coefficient differs from the upper AZS blocks and lower insulation blocks; design matching is needed for stress transition.

Insulation Layer:

Materials: Multi-layer lightweight insulating blocks (e.g., alumina bubble blocks, lightweight mullite blocks), ceramic fiber boards/blankets, etc.

Design Key Points: Insulation layer design requires detailed thermodynamic calculation to balance "reducing heat loss" with "maintaining necessary bottom structural strength (preventing excessive softening and deformation)." Ensuring long-term volume stability and non-powdering at high temperatures is essential.

3. Reinforcement of Key Areas

Joint Management:

Dry Laying and Expansion Joint Provision: Bottom blocks should preferably use precision-machined dry laying, in conjunction with high-quality refractory mortar (e.g., matching AZS-based mortar) for thin-joint masonry (<1mm). Thermal expansion joints must be precisely calculated, pre-planned and reserved, and filled with flexible materials like ceramic fiber blankets.

"Labyrinth" Sealing: In multi-layer structures, joints between layers should be staggered to avoid forming direct vertical paths.

Sealing Around Inserts (Bubblers, Electrodes, etc.): This is an extreme weak point for erosion. Specially designed combined block shapes, high-quality corundum-based or AZS-based ramming masses/castables must be used for tight sealing, forming reliable mechanical fixation and chemical barriers.

Third Level: Refined Construction, Heating, and Maintenance – Ensuring Perfect Realization of Design Intent

Precision Construction: Bottom laying is "fine work," requiring absolute flatness and uniform joint width. High-precision tools like laser alignment should be used.

Scientific Heating Curve: Develop and strictly execute a heating curve matching the refractory material properties, especially requiring slow heating below 600°C to fully remove physical and crystalline water, avoiding steam pressure-induced bursting. Adequate soaking at key temperature points (e.g., near the crystalline transformation temperature of AZS blocks) is necessary.

Operation Monitoring and Maintenance:

Temperature Monitoring: Embed thermocouples at different bottom locations to monitor temperature changes and gradients in real-time, providing early warning of abnormal erosion or insulation failure.

Emergency Response Plan: Prepare high-quality hot repair materials (e.g., sintered or fused AZS-based ramming masses), water cooling pipes, and other emergency tools and plans to address localized excessive erosion.

Erosion protection for glass furnace bottoms is a systematic engineering challenge spanning the entire lifecycle of design, material selection, construction, and operation. Future development trends will focus more on:

1. Material Advancement and Customization: Fused refractories with higher purity, optimized phase composition, and fewer defects (e.g., R&D on AZS without grain boundary phase), and fully customized brick shapes for specific glass compositions and furnace locations.

2. Structural Integration and Prefabrication: Promoting large-size integrated prefabricated components, and even composite techniques like overall bottom casting (using ultra-low cement wear-resistant castables) with inlaid high-grade blocks at key areas, to thoroughly eliminate joints.

3. Intelligent Monitoring: Utilizing IoT technology, combined with thermal imagers, erosion models, and big data analytics, to achieve online diagnosis and life prediction of bottom erosion status.

4. Design Simulation: Through coupled Computational Fluid Dynamics (CFD) and reaction kinetics simulations to accurately model erosion behavior under different material configurations during the furnace design phase, enabling virtual optimization.

Ultimately, the most economical bottom solution is not the one with the lowest initial cost, but the one that, over the entire furnace campaign, ensures stable, efficient, high-quality production and achieves safe, long-life operation with the lowest total cost. This requires close collaboration among glass manufacturers, furnace designers, and refractory suppliers to jointly build a protection community based on deep understanding.

Henan SNR Refractory Co., Ltd. has been specializing in the production of fused cast AZS blocks for more than 25 years. We use high-quality raw materials and advanced fusion and casting technology and equipment to provide customers with high-quality products. From raw material procurement to finished product delivery, every step is strictly quality inspected to ensure that every indicator meets the standards, so you can use it with confidence.

Should you have any inquiries or specific requirements, our team is ready to provide professional support and tailored solutions.

Contact Information:

Contact Information:

Web: www.snr-azs.com

Email:wendy@snrefractory.com